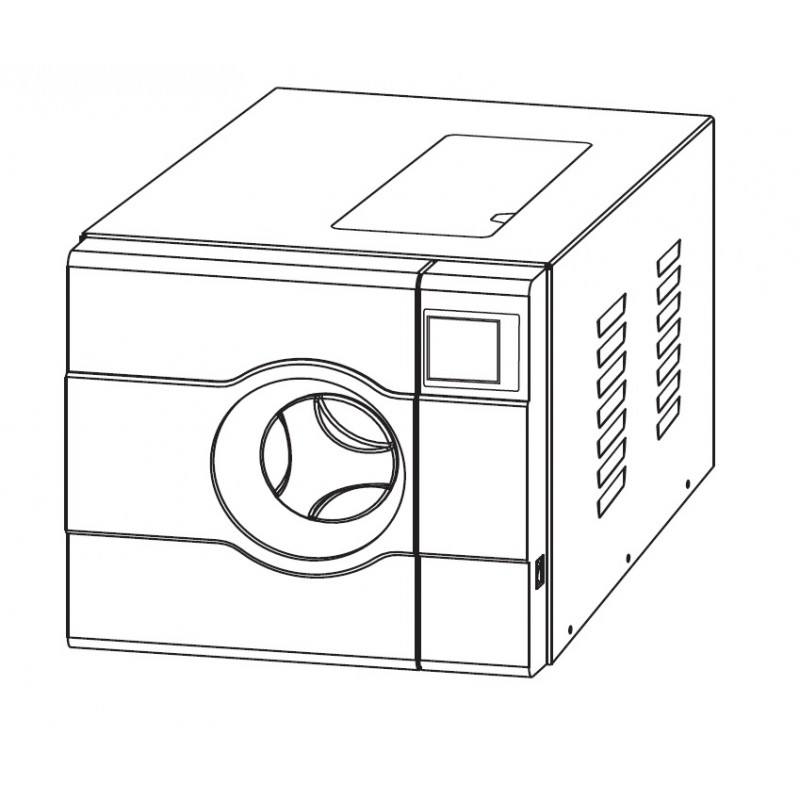

About Horizontal rectangular autoclave

The Horizontal Rectangular Autoclave Sterilization System is a one-of-a-kind and cutting-edge cold sterilizer used in the laboratory. Its triple-walled products are the best choice for mission-critical applications that call for the guaranteed and dependable elimination of all microorganisms capable of life.

The working individuals are protected against the possibility of an explosive opening as a result of this precaution. They also provide the characteristics listed below.

- Versatile usage

- Ergonomic Design

- Uses Less Energy Than Others

- Arrangement for Double-Stage Radial and Safety-Based Locking

- Protection from Two Separate Safety Valves

- Hydraulic Testing a pressure that is up to 2.5 times the normal operating pressure

Uses Of Autoclave

Horizontal autoclaves are highly preferred all over three world, as they are used in industrial, medical, education and research sectors. The sterilizer units are fitted by using rectangular pressure vessels which turn out to be excellent if your prime task is to sterilize the flat trays of surgical equipment. The rectangular vessel will turn out to be a hindrance if it is used for testing materials or for processing waste loads. You can procure the best quality horizontal rectangular autoclave from the reputed leading dealer or supplier at affordable rates.

Use Of Autoclaves In Industries

Does the size of horizontal autoclaves really matter in the world of sterilization?

Manufacturers offer horizontal autoclaves in two chamber formats. The formats are rectangular and round with front loading designs. When you buy a horizontal rectangular autoclave, then you should take into consideration the one which has a water or steam jacket. This puts pressure on the vessel mainly around the prime sterilizing chamber. You can procure this autoclave at cost-effective rates which comes with a more energy efficient solution.

The best quality horizontal rectangular autoclave can be obtained from the top-rated autoclave manufacturers at a relatively standard price.

Horizontal rectangular autoclave manufacturers have also made technological advancements, such as the addition of microprocessors, which assist users to sterilize equipment in accordance with the prescribed amount of time and display the temperature and pressure of the machines. Because it uses the air that is already present in the environment and consumes only a small amount of power, the operating costs are very low. This is in comparison to the costs associated with operating an autoclave machine. Once the process is finished, the only residue that is left behind is oxygen.

About Ozone Sterilizers

Horizontal rectangular autoclave is different from Ozone Sterilizers. Ozone is the most potent oxidizing agent that may be produced by natural processes. Ozone is able to kill bacteria, viruses, and other pathogens that might potentially contaminate the surface or the air thanks to the additional free radical oxygen molecule that it contains. In addition, unlike other types of detergents or synthetic cleaners, ozone does not leave behind any chemical residue, and if it is used correctly (by, for example, being converted back into oxygen molecules), it has the potential to be one of the most efficient methods of disinfection. Ozone is a strong and natural purifier, and today, with the introduction of the Ozilla Ozone Sterilizer, several firms have made it safer and simpler than it has ever been to utilize ozone gas for the prevention of infection and for a variety of applications requiring sterilization.

The Ozilla Sterilizer does not make use of any liquids, potentially dangerous ultraviolet rays, chemical treatments, or heat. Additionally, it does not ruin any surfaces and does not leave any chemical residues remaining. This is the best part about this product.